High load design / Dedicated high-load materials and heat treatment / Ball retainer / Circulation design with high d•n value / High lead design / High sealing performance / Bearing design

High Sealing Performance

Heavy-Load

Ball Screw

Highlights

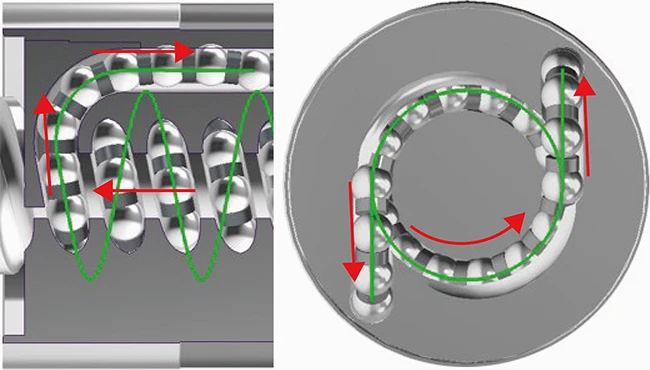

Ball retainer

The ball retainer is used, which reduces collision of steel balls during high-speed movement, effectively reduces torque fluctuation, and improves sound quality.

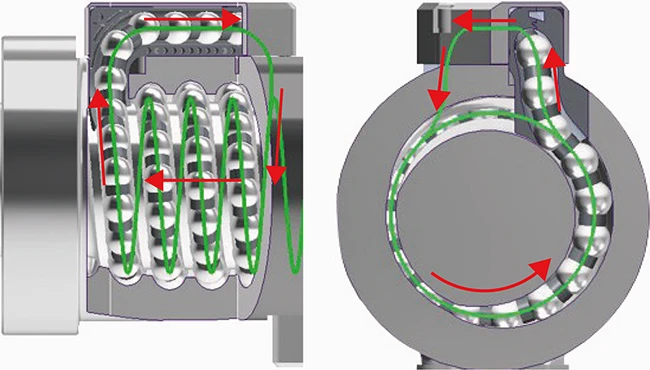

Circulation design with high d•n value

Steel balls move smoothly along the helical line of the screw shaft, reducing the shock of the steel balls on the circulating part. The d•n value (shaft diameter x speed), which is used as a high-speed performance evaluation index of ball screws, is increased to more than twice that of the previous bobbin insertion circulation mode.

HSP circulation mode

HSP circulation mode

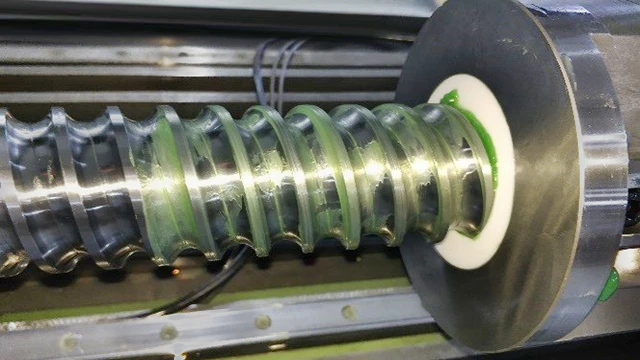

High sealing performance

A sealing ring with high sealing performance can effectively prevent splash of lubricating grease, so that lubricating grease retention is greatly improved. The unique sealing structure fits more closely to the spiral track surface of the screw shaft, significantly improving dust-protected and grease retention capabilities.

Before improvement

Labyrinthine sealing ring

After improvement

Sealing ring with high sealing performance

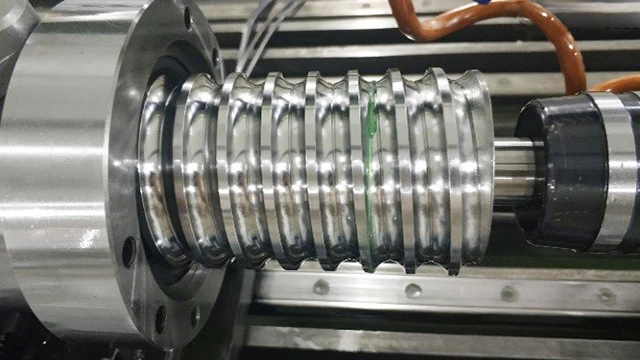

High lead design

The high-load series of ball screws from LAIEN can achieve ultra-high leads (the ratio of the shaft diameter to the lead is 1:1) and high d•n values, enabling a high-speed feed.

Noise reduction design

Allowing steel balls to move smoothly along the helical line of the groove can reduce the shock of the circulating part on steel balls and the noise level of ball screws during operation.