High-precision integration / Lightweight and easy to use / Heavy load / Low noise / High stiffness

Easy high-speed precision driving

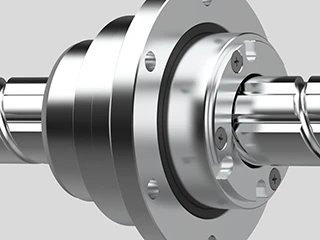

Ball Spline

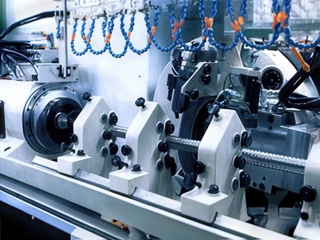

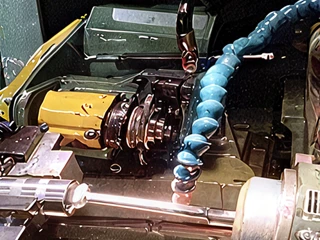

Grinding of ball screw external thread raceway

Guide circulation structure on end

Precision grinding for internal thread of nut

High-frequency induction hardening equipment

Use internationally advanced high-frequency induction hardening equipment for heat treatment of the ball screw, and strictly control the depth and consistency of the hardened layer, to achieve the expected lifetime of the product.

Highlights

High-precision

integration

The screw threads are Gothic threads. After preload is applied, the axial clearance in the rotational direction is zero, achieving high-precision positioning.

Based on rotary motion of ball screws and axial motion of the spline nuts, the ball spline and ball screw can move in linear, rotational, or helix mode, with high product integration.

Lightweight

and easy to use

The integrated design of the nut and support bearing ensures that steel balls will not fall even if the spline nut is pulled out of the spline shaft.

The precision ball spline is lightweight and smaller in size, requiring smaller installation space.

Heavy load

Consistent groove curvature, pressure angle, and out of roughness on the surface of working raceways ensure the high load and high rated dynamic load.

Low noise

The end bracket backflow design and the high-stiffness and wear-resistant materials effectively reduce torque fluctuations and friction, improve sound quality, and facilitate smooth motion between components.

High stiffness

The precision screw support bearing and precision spline support bearing are designed with a 45 ° contact angle and withstand the same axial and radial forces, providing high axial and radial stiffness.

Precision ball spline and Ball screw

- Imported materials and heat treatment processes can result in good precision retention.

- The axial clearance is 0, which allows for high-precision positioning.

- The innovative design prevents no-load steel balls from circulating around the perimeter, and the outer diameter of the spline nut is smaller, requiring smaller installation space.

- The nut and the support bearing are integrated. The nut is lighter and smaller, achieving a miniaturized, lightweight, and highly responsive design.

Application fields

- SCARA robot

- Automatic loader

- Assembly robot

- ATC device of machining center