High speed / High precision / Low noise / High reliability

Easy high-speed precision driving

Precision

Ball Screw

Guide circulation structure on end

Precision grinding for internal thread of nut

Precision grinding for external thread of screw shaft

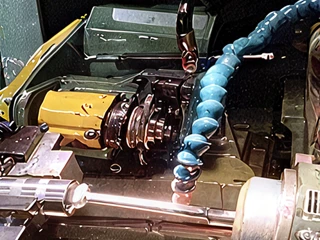

High-frequency induction hardening equipment

Use internationally advanced high-frequency induction hardening equipment for heat treatment of the ball screw, and strictly control the depth and consistency of the hardened layer, to achieve the expected lifetime of the product.

Highlights

High speed

The guide circulation structure on the end is optimized to return the balls along the helical lines, significantly reducing noise and temperature rise at high speeds.

The d•n value can reach up to 150,000.

High precision

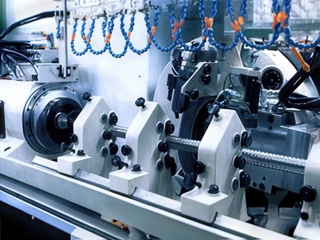

Japanese precision grinding technology is applied to the outer raceway of the screw shaft and the inner raceway of the nut.

The CNC precision trimming device accurately controls the shape of the groove for excellent precision performance.

Low noises

During frequent starts and stops and heavy load, ball screws will encounter severe wear and preload disappearance.

End plug circulation is adopted for balls to run smoothly along helical lines, reducing shock and making operation smoother.

High reliability

Customized raw materials, NTN screw design technology, and internationally advanced manufacturing equipment and processes maintain long-term precision stability of products and improve the load capacity by 20%.

High-speed precision ball screws of BS series

- Customized imported raw materials and heat treatment processes can result in good precision retention.

- Nuts of the same length have a greater bearing capacity for the end plug structure than the internal circulation structure.

- The d•n value can reach up to 150,000.

- The end plug structure allows for smoother ball circulating transitions, significantly reducing noise and temperature rise.

Application fields

- It is applicable in fields of CNC equipment, such as machining centers, CNC lathes, CNC grinding machines, engraving machines, and electric machining machine tools.

- It is suitable for occasions requiring quick and largeforce movements, such as all-electric injection molding machines and hydraulic presses.

- It is applicable in industries such as medical, transportation, and welding pliers.